FHT SYSTEM

FHT is our mid-range system that allows a simple zone heating of your house, plus additional simple automation such as lights control, window rollers, wireless alarm, etc. It uses a Central Control Unit that polls the status of all networked components and allows a quick and remote intervention. The CCU also works in conjunction with the Heat Demand Relay to either stop the boiler, or the re-circulation pump when optimal temperature is reached in each zone.

It was designed to avoid wall alteration through conduits for new wiring and connection boxes for wall thermostats and switch buttons; instead, all devices are battery powered (except the Central Control Unit), wireless and self-adhesive for easy and convenient placement in the room. The wireless thermostatic head fits a multitude of existing radiator valves either directly to the M30x1.5 thread, or through the provided adapters; additional Actuator Valve Adaptors are available. Communication between devices is done at five minutes intervals, which allows a battery life of two years. And if you ever move, taking the MAX! SYSTEM with you is just as easy - removing the system will leave no permanent marks...

SETUP WITH NETWORK CONTROL (FHZ1000 / FHT80B / FHT8V / FHT8W):

- First, unscrew the old TRV head and insert the Actuator (FHT8V) in their place – no intervention in the heating system required, the Actuator uses the existing valve attached to the radiator.

- Then, through a simple operation, pair the room Actuators (FHT8V) with the Wall Thermostat (FHT80b) for each room (i.e. zone) - if a zone has more than one radiator, all corresponding Actuators have to be taught into the Wall Thermostat (up to 8 Actuators per Wall Thermostat).

- One zone can be covered by the Central Control Unit (FHZ1000) which has similar functions to the Wall Thermostats. After registering the Wall Thermostats with the CCU, users can also control the temperature in the other zones from the FHZ1000.

- Finally, the CCU and the Wall Stats are paired with the Heat Demand Relay (FHT8W) which, in turn controls the boiler. The heating programs (2 ON, 2 OFF cycles per day) are set directly on the CCU / Wall Stats.

SETUP WITHOUT NETWORK CONTROL (FHT8SET / FHT8W):

The setup of the FHT Economy Set (FHT8SET) is similar, but cannot interact with the CCU – control of each zone is done from the Wall Thermostat only. Connection to the Heat Demand Relay is enabled.

OPERATION:

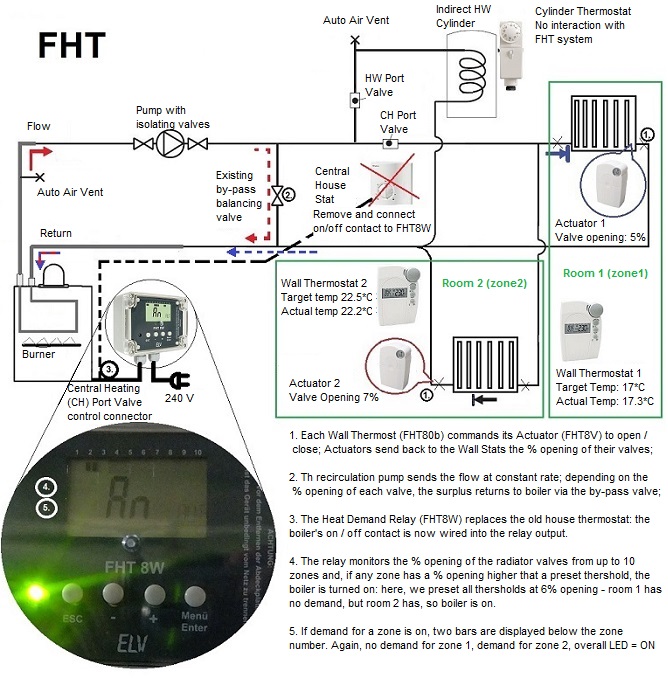

The CCU and the Wall Thermostats are constantly monitoring the temperature of the zone they are place in: if the actual temperature is lower than the target temperature, the stat send a signal to the Actuator to open the radiator valve; if actual temperature is higher that the target one, the stat sends a signal to close the valve. The opening / closing is done gradually – the actuators transmit back to the stat the % opening of the valve. System override can easily be made from each Wall Thermostat / CCU by pressing the SUN (comfort temperature) or MOON (reduced temperature) program button, or by manually controlling the zone.

BOILER INTERACTION: The Heat Demand Relay uses the ON/OFF contacts of the old house thermostat to control the boiler. It is in constant contact with the CCU / Wall Thermostats (up to 10 zones) from where it receives the % opening of the valves. Users define a % opening threshold for each zone and the Heat Demand Relay compares the threshold to the actual opening – if all zones have the % opening below their corresponding threshold, there is no heating demand and so the relay shuts-off the boiler. If only one zone demands heating (% opening of the valve in the zone higher that the zone’s threshold), then the relay starts the boiler.

WEB CONTROL:

At this moment, there is no web control enabled. Users can combine this system with the MAX! and use a MAX! Cube LAN Gateway and a MAX! Switched Power Outlet to control the remote starting / stopping of the boiler – once started, the FHT system resumes it’s monitoring.

It was designed to avoid wall alteration through conduits for new wiring and connection boxes for wall thermostats and switch buttons; instead, all devices are battery powered (except the Central Control Unit), wireless and self-adhesive for easy and convenient placement in the room. The wireless thermostatic head fits a multitude of existing radiator valves either directly to the M30x1.5 thread, or through the provided adapters; additional Actuator Valve Adaptors are available. Communication between devices is done at five minutes intervals, which allows a battery life of two years. And if you ever move, taking the MAX! SYSTEM with you is just as easy - removing the system will leave no permanent marks...

SETUP WITH NETWORK CONTROL (FHZ1000 / FHT80B / FHT8V / FHT8W):

- First, unscrew the old TRV head and insert the Actuator (FHT8V) in their place – no intervention in the heating system required, the Actuator uses the existing valve attached to the radiator.

- Then, through a simple operation, pair the room Actuators (FHT8V) with the Wall Thermostat (FHT80b) for each room (i.e. zone) - if a zone has more than one radiator, all corresponding Actuators have to be taught into the Wall Thermostat (up to 8 Actuators per Wall Thermostat).

- One zone can be covered by the Central Control Unit (FHZ1000) which has similar functions to the Wall Thermostats. After registering the Wall Thermostats with the CCU, users can also control the temperature in the other zones from the FHZ1000.

- Finally, the CCU and the Wall Stats are paired with the Heat Demand Relay (FHT8W) which, in turn controls the boiler. The heating programs (2 ON, 2 OFF cycles per day) are set directly on the CCU / Wall Stats.

SETUP WITHOUT NETWORK CONTROL (FHT8SET / FHT8W):

The setup of the FHT Economy Set (FHT8SET) is similar, but cannot interact with the CCU – control of each zone is done from the Wall Thermostat only. Connection to the Heat Demand Relay is enabled.

OPERATION:

The CCU and the Wall Thermostats are constantly monitoring the temperature of the zone they are place in: if the actual temperature is lower than the target temperature, the stat send a signal to the Actuator to open the radiator valve; if actual temperature is higher that the target one, the stat sends a signal to close the valve. The opening / closing is done gradually – the actuators transmit back to the stat the % opening of the valve. System override can easily be made from each Wall Thermostat / CCU by pressing the SUN (comfort temperature) or MOON (reduced temperature) program button, or by manually controlling the zone.

BOILER INTERACTION: The Heat Demand Relay uses the ON/OFF contacts of the old house thermostat to control the boiler. It is in constant contact with the CCU / Wall Thermostats (up to 10 zones) from where it receives the % opening of the valves. Users define a % opening threshold for each zone and the Heat Demand Relay compares the threshold to the actual opening – if all zones have the % opening below their corresponding threshold, there is no heating demand and so the relay shuts-off the boiler. If only one zone demands heating (% opening of the valve in the zone higher that the zone’s threshold), then the relay starts the boiler.

WEB CONTROL:

At this moment, there is no web control enabled. Users can combine this system with the MAX! and use a MAX! Cube LAN Gateway and a MAX! Switched Power Outlet to control the remote starting / stopping of the boiler – once started, the FHT system resumes it’s monitoring.

-

FHT 80b Wall Thermostat

£34.99Out of stock

-

FHZ1000 Central Control Unit

£85.99Out of stock

-

FS20 DI22 wireless dimmer

£45.00